Master Data

Master Data is the back bone of your business, it has to be accurate and has to be maintained. For a manufacturing facility there are many facets of master data. Equipment, material masters, bill of material, vendors are four of the more critical items that if built correctly will help with both the processing of transactional data and for month end / year end analytics.

Experience - we are proud to have been given he responsibility of managing the build of SAP asset data for a major oil operators refinery extension. This $6bn capital project resulted in over 50,000 asset records that where structured per IS0 14224 and needed 6,000 new material masters for the 5,000 bills of material. Not forgetting the 7,000 maintenance plans and routes. We supplied the tools, build methodology, program management and SAP expertise, the business provided the resources and site knowledge ... references are available on request.

The Tools

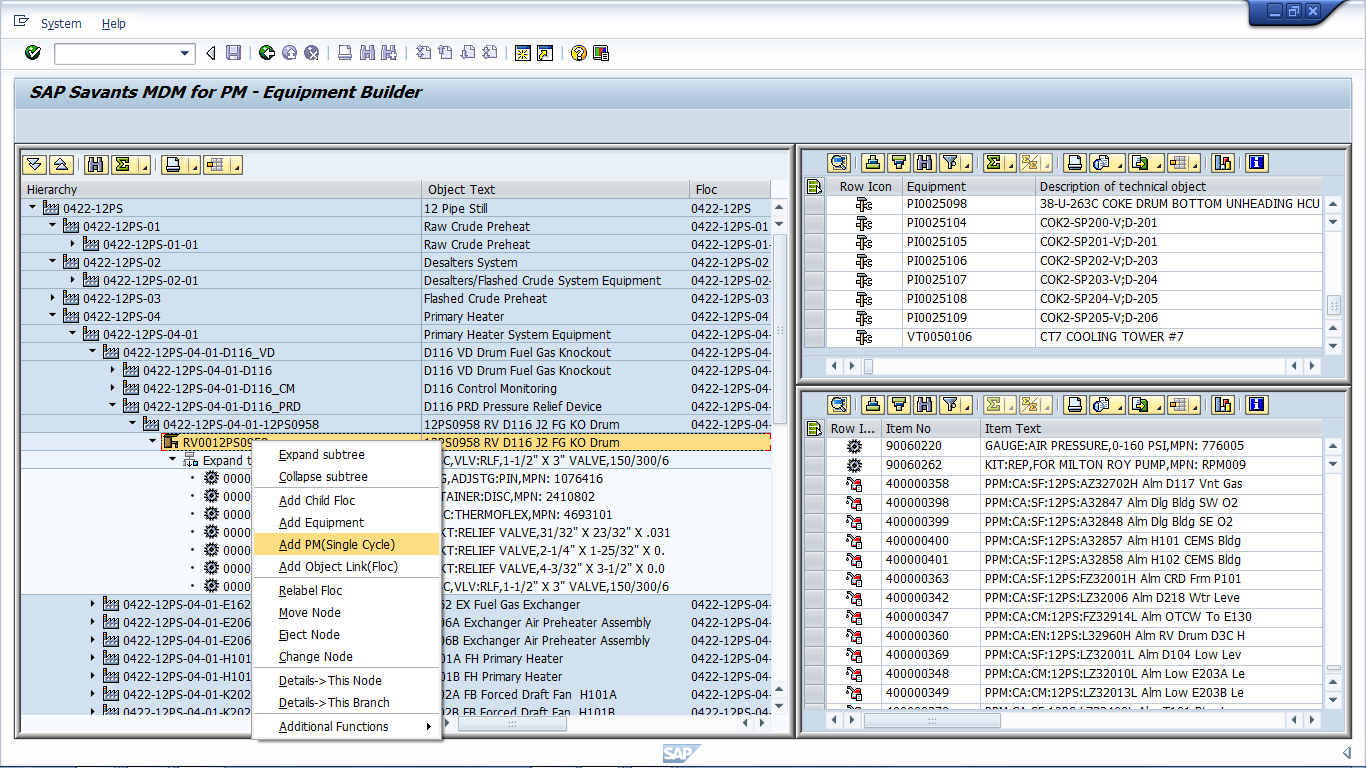

SAP Savants Equipment Builder - is a custom SAP transaction that puts all of the data required to build and maintain asset intensive information into a single work space. The hierarchy shows Locations, Equipment, Materials with full inventory details, Maintenance plans with items and object list, dedicated task lists, object links (we cannot fully emphasise how powerful this feature is ... click here to find out ...), notifications, maintenance orders, classification. Right click to add, change and remove records, mass change, export to excel or LSMW. Import equipment data from projects and drag/drop into the tree ... publish when the project build is complete.

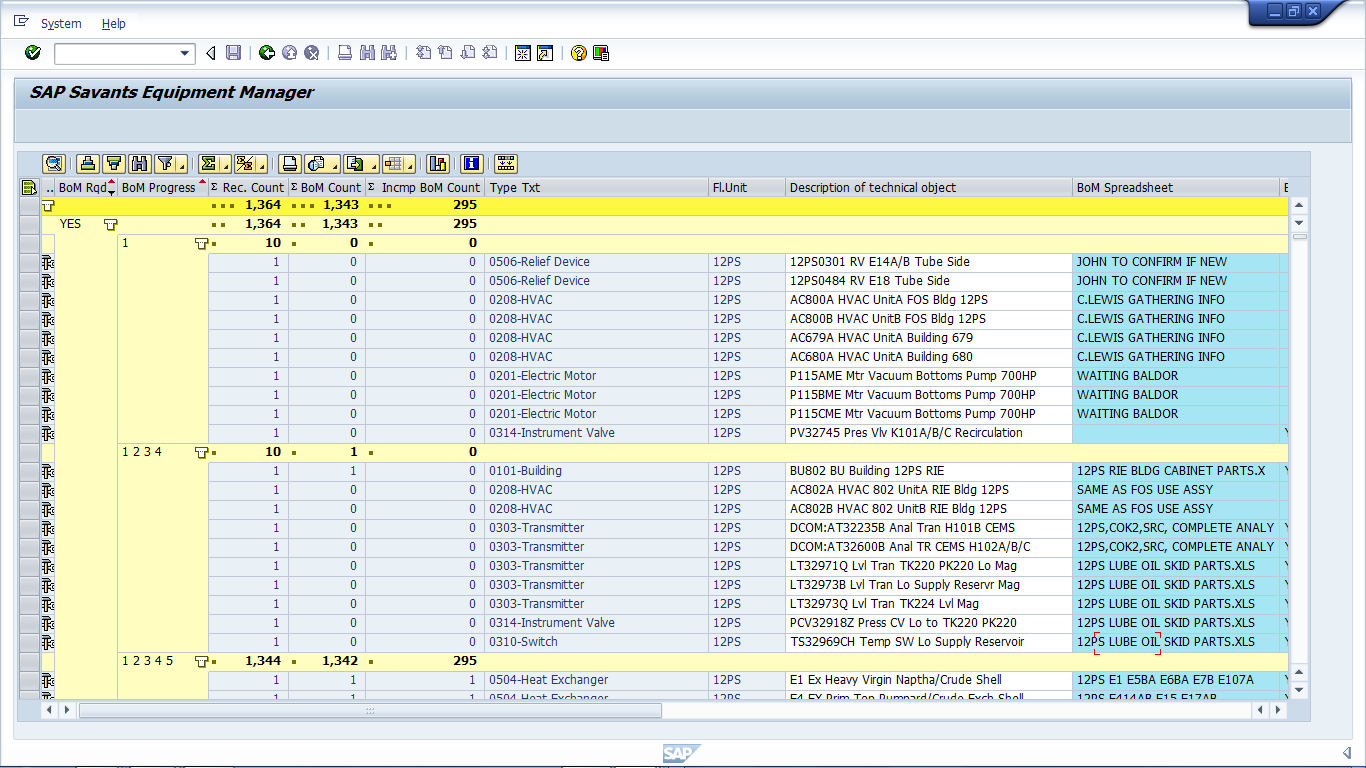

SAP Savants Equipment Manager - Is a custom SAP transaction that puts all of your functional location/equipment centric data into a single work space. Information that is available for each asset record including BoM count, PM count, Object list Count and also a 1 base count for each record ... you can also specify to include data from up to three classes. Click here to read how we used this report to manage the PM and BoM build for a refinery that was installing a new Coker unit.

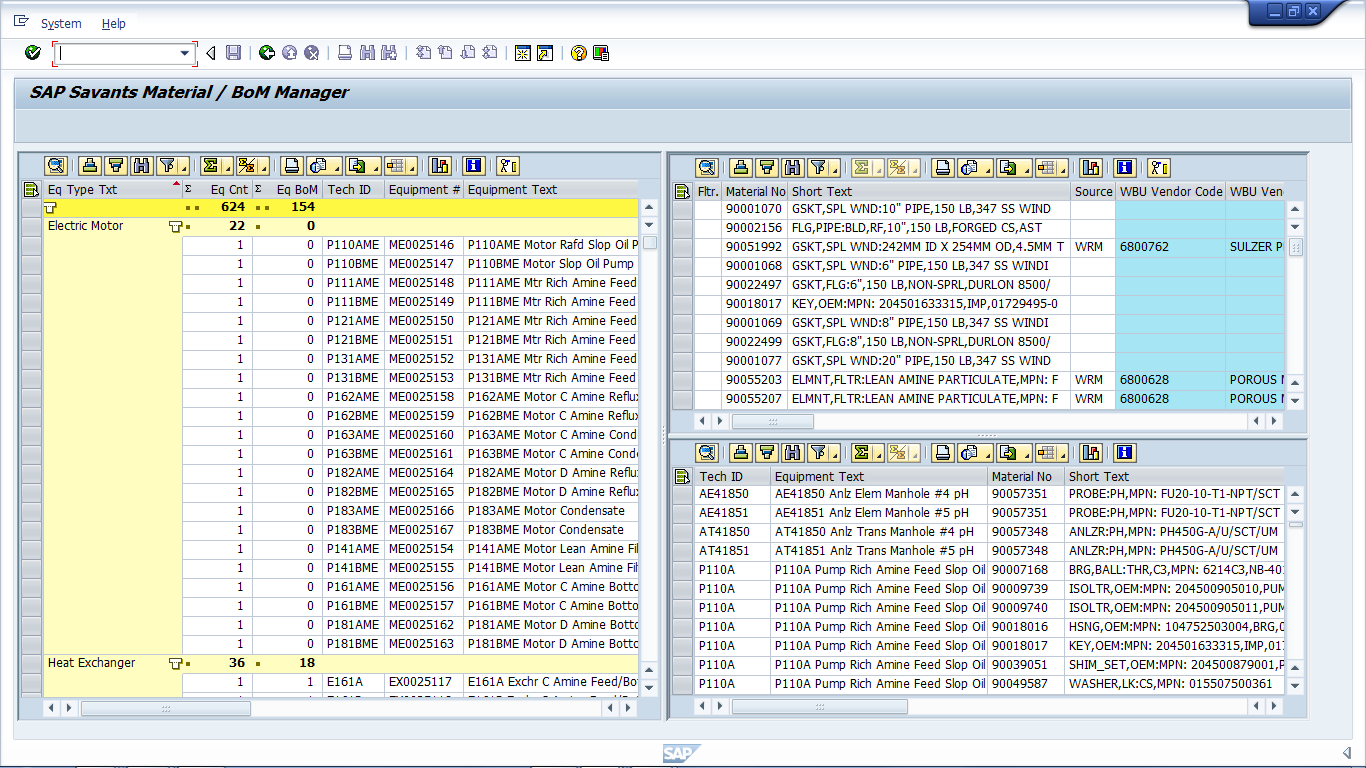

SAP Savants BoM Manager - Is a custom SAP transaction that puts all of the information related to Bills of Material, Equipment, Material Masters, Inventory, Where Used into a single work space. Output can be material or equipment centric, you choose where to start and the transaction will gather all of the related data. Providing an equipment or material list will get all related material data, including MRP information, inventory levels, BoM/where used data including material and equipment criticality. Click here to see how we used this data to provide clarity on the setting of min/max levels for critical equipment spares.

Building Master Data

We take an SAP centric approach to the building of master data, why reinvent the wheel with an external application when all of the tools needed are available in your existing SAP system. We do have a few custom transactions that help pull the information together and provide improved reporting and management functionality. These are installed via an SAP transport at a fraction of the cost procuring and interfacing with third party products.

Data records can be imported from third party systems and structured into the functional location / equipment hierarchy via drag and drop functionality. New records can be created via a right click or can be copied from predefined templates for pump skids, exchangers et al. We use object links to work within existing structures but are able to keep data from being visible to production users. When the build is complete it is imported into the existing structure by replacing the object links with actual locations.

The classification system is used for management reporting ... click here to see how ... and the ECM is used to keep changes to existing BoMs and tasklist 'hidden' until the build is complete.

Maintaining Master Data

There are a number of ways to communicate the need for a change master. Some that we have seen are; sharepoint forms with workflow, Lotus Note, SAP notifications (sometimes with custom sub screens), emails (hope not) even SAP latest Management of Change module ... click here for details. We have a fully documented master data management workflow that includes the creation, updating and disposal of assets and related data.

Once the change is communicated it then has to be executed. The same tools that we use to build the master data are, fortunately, the same tools that are used to maintain the master data. They provide quick access to all impacts of the change ( for example a simple click will list all data ... equipment, instrumentation, materials (with inventory balance and where used), PMs, Notifications, Orders and POs ) enabling quick execution of the request.

Mass updating is supported so that each affected record can be updated with the request id / details and appropriate user and system statuses set.